Characteristics and application fields of copper clad steel strand

If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

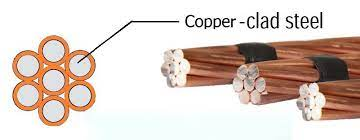

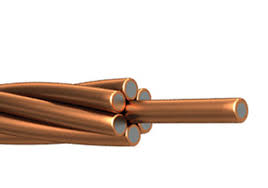

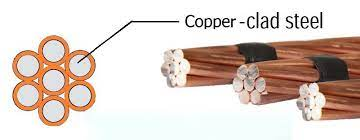

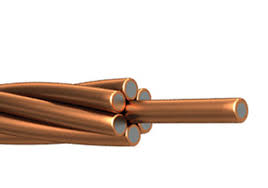

Copper clad steel stranded wire is made of a certain number of copper-plated single wires twisted by a stranding machine. As the name suggests, copper clad steel is a round steel surface electroplated, so it is a composite cord with a copper layer twisted around the steel round cord. It utilizes the skin effect of low-voltage and high-frequency signals to stroll along the surface in the high-frequency location, so as long as the copper layer thickness reaches a certain range, the signal in a certain frequency range can be guaranteed to be transmitted. Copper plays the role of conducting weak electrical signals, and the steel round wire plays a supporting role. According to the different methods of wrapping copper to steel round wire, it is mainly divided into electroplating, coating, hot casting/immersion and electroforming. This item integrates the toughness and durability of steel with the excellent electric conductivity and deterioration resistance of copper. Compared with copper single cord, it has the advantages of low thickness, high toughness and low cost. It is an updated product of traditional pure copper single wire.

copper clad steel strand is a new composite material processed by evenly electroplating electrolytic copper molecules with a content of 99.9% onto a high-quality low-carbon steel core. This product has the strength and toughness of steel as well as the good conductivity and conductivity of copper. Corrosion resistance. Products are widely used in high-frequency coaxial cables, steel network communications, electrified railways, subway light rails, round wires in power and petrochemical systems, etc. Compared with pure copper, copper-plated steel stranded wire has the advantages of low density, high strength, and low cost. It is an updated product of traditional pure copper stranded wire.

Features of copper clad steel strand:

1. Unique manufacturing process

The material is manufactured using a special process to achieve metallurgical molecular bonding and long service life.

2. Soft structure, large surface volume and good heat dissipation effect.

Using high-temperature welding, there is no residue and no corrosive phenomena. The surface copper layer is thick (conductivity is as high as 30%), has strong corrosion resistance, has a long service life (more than 30 years), and is maintenance-free.

3. Better electrical performance

The skin effect principle, excellent electrical conductivity, and its magnetic permeability properties are conducive to the diffusion and transmission of electromagnetic fields.

4. Safe and reliable

Using special connectors or chemical exothermic welding, the joints are firm and stable.

5. Convenient and fast

Using special heat treatment, it can be made into a soft state, with a large length and a large number of straight-line connection points.

6. Wide usability:

Packed into traps or trays, with few connection points and easy transportation.

l Based on the principle of skin effect, its electrical conductivity is equivalent to that of pure copper wire, and its excellent magnetic conductivity facilitates the transmission and diffusion of lightning present.

l Light weight, high strength and easy to install.

l Adopting special heat treatment, it can be made into a soft state, large length, and a large number of straight-line connection points.

l Made by four-dimensional electroplating barrel plating process, metallurgical melting and casting molecular bonding, lengthy life span.

Application fields of copper clad steel strand:

1. Covered wire conductor;

2. Electric power industry grounding rod;

3. Braided shielded wire of power cable;

4. Connectors for various electronic components;

5. Reinforced conductive core of special cables;

6. Power transmission and telephone lines that are placed above ground;

7. Conductors of parallel two-core telephone subscriber communication lines;

8. Load-bearing cables and trolley lines for electrified railways and rail transit lines;

9. Inner conductor materials of coaxial cables for cable TV subscriber lines and household lines;

10. Inner conductor materials for computer LAN, access network cables, and outdoor cables.

Among them, copper-clad steel stranded wire is widely used in the power field:

Transmission lines: As the main component of transmission lines, copper-clad steel strands play a vital role in power transmission. Its excellent electrical conductivity, high strength and toughness, and good corrosion resistance make power transmission lines more stable and reliable.

Substation: In substations, copper-clad steel stranded wires are widely used in the connection parts of various wires and cables, such as terminal blocks of transformers, circuit breakers, isolating switches and other equipment. Its excellent electrical conductivity and corrosion resistance ensure the safety and stability of substation operation.

Power distribution system: In power distribution systems, copper-clad steel stranded wires can be used to manufacture conductors in distribution lines, cable sheaths, and connecting wires in distribution boxes. Its high strength and toughness and good corrosion resistance make it widely used in power distribution systems.

Communication lines: Copper-clad steel stranded wires can also be used in communication lines, such as the wiring and transmission of telephone, Internet, cable TV and other communication systems.

Supplier

TRUNNANO is a supplier of copper clad steel materials with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality copper clad steel materials please feel free to contact us and send an inquiry.

Inquiry us